Where hollow sections are sealed they must be vented for reasons of safety so allowing the escape of air and the ingress and drainage of zinc during the dipping process. Vent holes are required at each sealed end either in the end plate or the section.

Where hollow sections are sealed they must be vented for reasons of safety so allowing the escape of air and the ingress and drainage of zinc during the dipping process. Vent holes are required at each sealed end either in the end plate or the section.

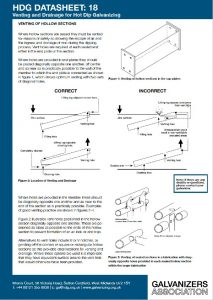

Where holes are provided in end plates they should be placed diagonally opposite one another, off centre and as near as is practically possible to the wall of the member to which the end plate is connected, which shows optimum venting with two sets of diagonal holes.

If there are any doubts or questions, please contact your galvanizer.

Due to the nature of internal venting, which is difficult to check, galvanizers will assume that internal venting has not been applied, once work is provided for galvanizing.

Want to have a pdf version of this datasheet? Click the button below.