Benefit of using galvanized steel in fire

The benefit of utilizing galvanized steel members for fire resistance is apparent in structures that require short fire resistance periods, that is, 15 or 30 minutes of fire exposure, where the temperature reached by the galvanized steel members is around 500°C.

Examples of structures that require such fire resistance periods include car parks and single-storey residential/office industrial buildings. There may also be benefit in using galvanized steel for other types of structures, such as single storey industrial buildings or some multi-storey office buildings, where the use of sprinklers may enable a reduction of the minimum fire period to 30 minutes.

Go to: Performance of galvanized steel in fire | Fire protection research

Design guide summary

This design guide provides tables to calculate fire resistances and maximum fire exposure periods for galvanized steel beams, composite beams, columns, and plates in tension, according to the Eurocode design standards (EN 1993-1-26, EN 1994-1-2) and the UK and Irish National Annexes.

The design tables are applicable for fire exposure periods of up to 30 minutes, and they clearly show the cases where the use of galvanized steel leads to an increase in fire resistance or fire exposure compared to non-galvanized steel. The Eurocode design tables are given in Appendix A. Additionally, design tables in accordance with BS 5950 are given in Appendix B.

Laboratory and full-scale testing have demonstrated that below approximately 500°C, a steel section that has been galvanized to EN ISO 1461 has a lower surface emissivity than non-galvanized steel. A galvanized steel section will therefore heat up at a slower rate than an equivalent non-galvanized section.

The lower temperature rise will lead to increased fire resistance for fire exposure periods of up to around 30 minutes.

For sections with moderate section factors (105 m-1< ksh [Am⁄V]m < 182 m-1) the effect is more noticeable for a 15 minute fire resistance period. However, for sections with low section factors (33 m-1< ksh [Am⁄V]m < 64 m-1, the largest benefits are achieved at 30 minutes fire resistance. Sections with section factors falling within these ranges cover a large proportion of UB/UC/hollow sections.

Design examples are also provided to illustrate the use of the tables and the potential advantages of galvanized steel over non-galvanized steel in fire (e.g., increased load resistance or longer fire exposure period for a given load).

Performance of galvanized steel in fire

Due to the reduction in surface emissivity of the zinc coating described in the previous section, galvanized steel members may experience a smaller temperature increase equivalent non-galvanized steel members.

The benefit of the reduced emissivity is most significant for structures that require shorter fire resistance periods, such as car parks or single storey industrial buildings, where the temperature reached by the galvanized steel members is around 500°C. The reasons for this are:

- for temperatures lower than 500°C, the rate at which the temperature increases in a galvanized steel member is given by a surface emissivity of 0.35, while for a non-galvanized steel member this is given by a surface emissivity of 0.70;

- steel strength is most sensitive to temperature at around 500°C, and so in this temperature range, small differences in temperature have a pronounced effect on strength loss.

For temperatures below 400°C, steel does not show any loss in strength. Therefore, for temperatures of around 400°C, even though the temperature in a galvanized steel member is lower than that in an equivalent non-galvanized steel member, this does not necessarily translate into a significant difference in strength.

On the other hand, for temperatures higher than 500°C, the surface emissivity of galvanized steel is the same as that of non-galvanized steel (0.70), and therefore, as the temperature increases, galvanized steel and non-galvanized steel temperatures converge.

Another important factor that affects the rate at which the temperature in a steel member increases is the section factor. In EN 1993-1-2, the section factor is defined as the surface area of the member exposed to a fire per unit length, Am, divided by the volume per unit length, V. Therefore, a beam exposed to a fire on four sides has a higher section factor than an equivalent one exposed on three sides.

This factor has the same effect irrespective of whether the section is galvanized or non-galvanized, as it only depends on the geometric proportions of the cross-section. That is, the larger the section factor, the faster the temperature in the member increases. As a result of this, the largest benefit of using galvanized steel over non-galvanized steel can occur in different cross-sections at different fire exposure times, depending on the section factor of the cross-section.

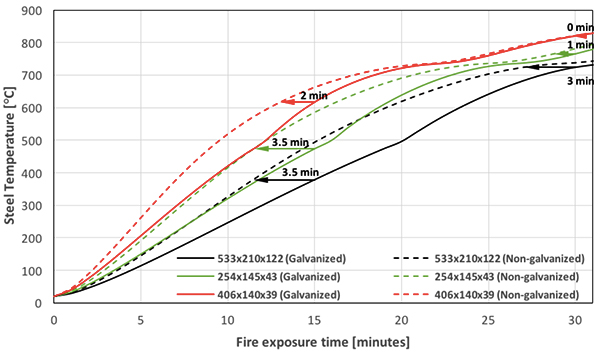

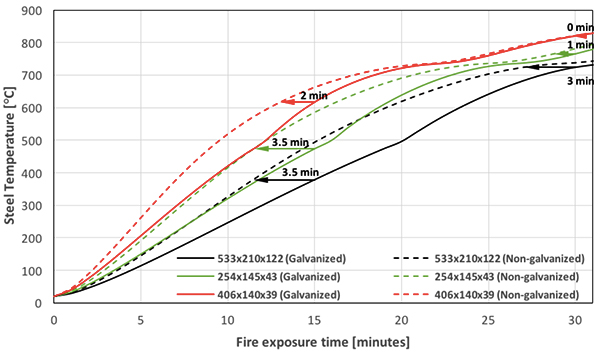

Figure 1 compares the rise in steel temperature of galvanized and non-galvanized steel beams for three different Universal Beam sections:

– 533 x 210 x 22

– 254 x 146 x 43

– 406 x 140 x 39

The beams are exposed to fire from three sides with section factors ksh [Am⁄V]m of 75 m-1 109 m-1 and 170 m-1, respectively. The figure indicates that for a fire exposure period of 15 minutes, the galvanized steel sections can achieve 3.5 minutes, 3.5 minutes, and 2.0 minutes longer fire resistance period compared to the equivalent non-galvanized steel sections, respectively. For a fire resistance period of 30 minutes, the galvanized steel section with a section factor of 170 m-1 (UB 254 x 146 x 43) performs very similarly to the equivalent non-galvanized steel section. This is because at 30 minutes fire exposure, the temperature in the galvanized section is 820°C, which is significantly higher than 500°C. For the section with a section factor of 75m-1 (UB 533 x 210 x 122), however, at 30 minutes fire exposure, there is still a noticeable gain in fire exposure time of 3 minutes.

Figure 1. Temperature rise of galvanized and non-galvanized steel sections subject to the standard nominal fire curve

Figure 1. Temperature rise of galvanized and non-galvanized steel sections subject to the standard nominal fire curve

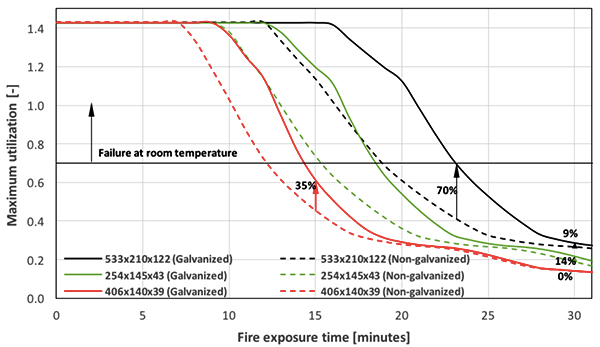

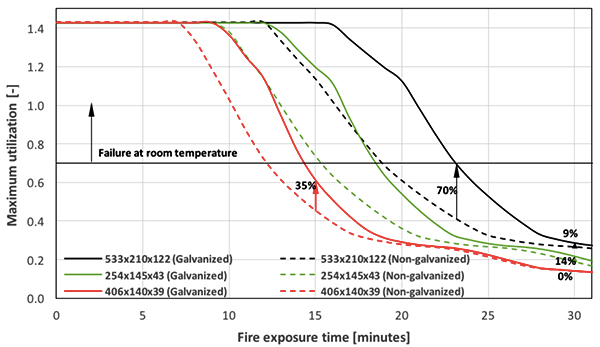

If the gains in fire exposure time using galvanized steel are translated into increased resistance, the advantages are more pronounced. Figure 2 compares the resistance versus time behaviour for the galvanized and non-galvanized steel beams previously discussed.

In the figure, the resistance is represented by the maximum utilization that can be achieved by the member, calculated as the ratio of the cross-sectional resistance of the beam in the fire situation to the cross-sectional resistance at room temperature. A degree of utilization of 0.7 is indicated by a horizontal line which corresponds to the largest practical value for which a laterally restrained beam can be designed in the fire situation. This is because beams designed in fire for a degree of utilization larger than 0.7 are likely to fail at room temperature.

Bearing this in mind, at 15 minutes of fire resistance, despite the galvanized sections UB 533 x 210 x 122 (with a section factor of 75 m-1 and UB 254 x 146 x 43 (with a section factor of 109 m-1) being able to achieve a greater utilization than their non-galvanized counterparts, there is no benefit in using galvanized steel over non-galvanized steel for these sections. On the other hand, for section UB 406 x 140 x 39, which has the largest section factor (170 m-1), the maximum utilization of both galvanized and non-galvanized cross-sections is below 0.70 at 15 minutes fire exposure. In this case, using galvanized steel leads to an increase in load carrying capacity of 35% compared to using non-galvanized steel.

For sections UB 533 x 210 x 122 and UB 254 x 146 x 43, the maximum utilization that can be achieved by the non-galvanized steel sections decreases below 0.7 at noticeably shorter fire exposures than that of the galvanized sections. For example, for the steel section with the lowest section factor (UB 533 x 210 x 122), at 23 minutes fire exposure, when the maximum utilization of the galvanized section decreases to 0.70, it can carry 70 % more load than the non-galvanized section. At 30 minutes of fire exposure, even though the gain in fire resistance time is low for sections UB 533 x 210 x 122 and UB 254 x 146 x 43 (see Figure 1), they show a modest gain of 9% and 14% in load carrying capacity, respectively (see Figure 2).

Generally speaking, a laterally restrained beam or a tension plate constructed from galvanized steel and with a section factor in the range of 105 m-1< ksh [AmV]m < 182 m-1 can carry above 30 % more load than a non-galvanized section at 15 minutes fire exposure. For laterally restrained beams, the lower bound of this section factor range depends on whether the beam is exposed to fire on three or four sides, or if it works compositely with the slab. Thus, while for beams exposed to fire on four sides the lower bound for the section factor is 105 m-1, for a beam exposed to fire on three sides, and for a composite beam this value is 145 m-1 and 115 m-1 respectively. For galvanized steel columns a similar increase in fire resistance at 15 minutes fire exposure is achieved if the section factor is in the range of 81 m-1 < ksh [Am⁄V]m < 190 m-1 For the design at 30 minutes fire exposure, an increase in fire resistance of more than 30 % can be achieved when the galvanized steel member has a section factor in the range of 33 m-1 < ksh [Am⁄V]m < 64 m-1.

Figure 2 Maximum utilization for galvanized and non-galvanized steel beams exposed to fire on three sides

Figure 2 Maximum utilization for galvanized and non-galvanized steel beams exposed to fire on three sides

Laboratory research – full scale testing

A number of researchers have observed that galvanized steel members reach lower temperatures during fires than equivalent non-galvanized steel members. It was postulated that this effect was due to the lower emissivity of the galvanized surface.

Emissivity values of 0.29 – 0.40 were proposed in several studies, compared to the emissivity of a non-galvanized steel surface of 0.7 which is widely used in the prediction of steel temperatures during a fire.

Although this effect has been recognized for several decades, it is only recently that sufficient weight of evidence has allowed a standardized emissivity value for galvanized steel to be determined.

According to Sala1, radiation of metal surfaces is based on atomic and molecular vibrations which depend on the chemical composition of a surface layer up to approximately 10-10 m thick. As the outer zinc layer of a galvanized surface has a thickness of 5 to 20×10-6 m, it is this layer which determines the radiation behaviour of galvanized steel.

The first tests of galvanized steel fire resistance

The first calorimeter tests to indicate the favourable influence of a galvanized coating on the temperature of steel during a fire were carried out by Heinisuo2. The specimens were subjected to a heat flow from a cone calorimeter. The derived value of emissivity of galvanized steel members below 420°C was determined as 0.2.

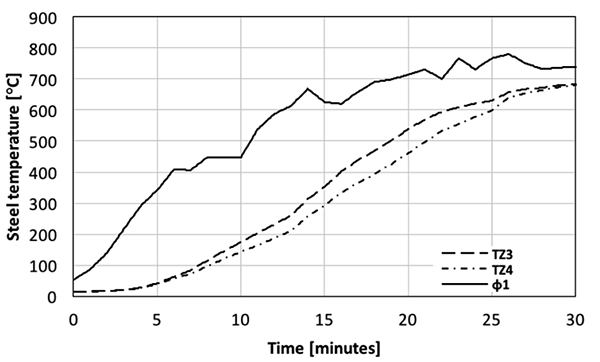

The Czech Technical University in Prague validated the surface emissivity of galvanized steel in typical fire conditions by carrying out two full scale furnace tests and also testing specimens in a compartment in an experimental building (Figure 3)3.

Figure 3: Test specimens suspended from the compartment ceiling

Open and closed steel specimens, one metre in length, were hung from the ceiling

of the compartment at the location of the highest expected gas temperature. The arrangement of the specimens ensured an even temperature distribution. Profiles were arranged in pairs (galvanized and non-galvanized). Specimens were isolated at both ends by mineral fibre wool such that the sample simulated an infinite length element and that heat transfer occurred only at the outer surface.

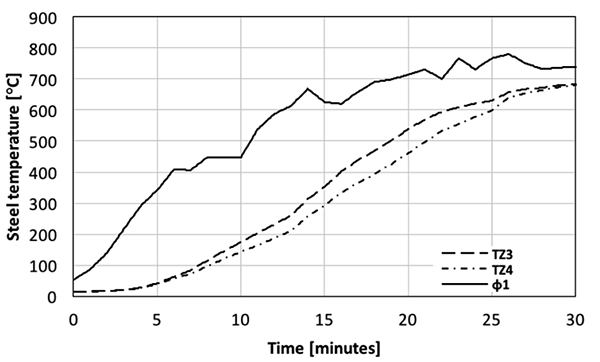

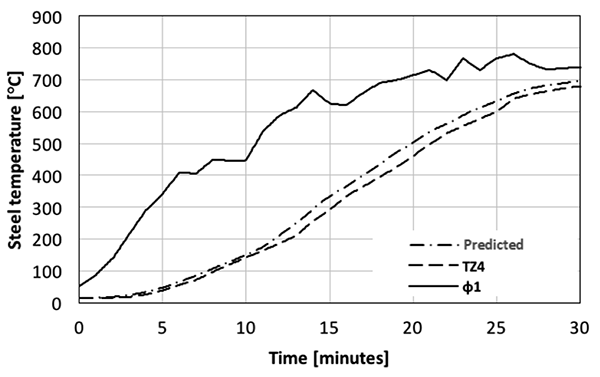

The temperature of each specimen was measured by one 2 mm diameter thermocouple, which was placed at the mid-point of each specimen. The gas temperature in the fire compartment was measured by twenty 3 mm thermocouples and seven plate thermocouples. Figure 4 shows the temperature rise of the specimens in the compartment.

Figure 4: Measured temperature rise during fire tests: gas temperature (φ1), galvanized IPE (TZ4) and non-galvanized IPE (TZ3)

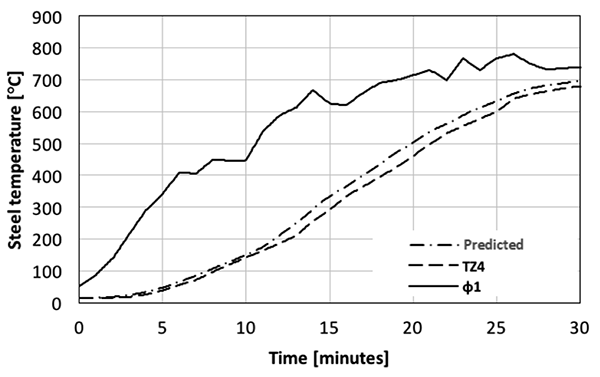

The measured temperature rise was compared against the predicted rise assuming a value for the surface emissivity of 0.32, which had been measured previously in horizontal furnace fire tests. Figure 5 shows the good correlation between the measured and predicted results, especially in the first 20 minutes of the fire.

Figure 5: Temperature rise during fire tests: measured gas temperature (φ1), measured and predicted temperature for galvanized IPE (TZ4), assuming an emissivity = 0.32

Figure 5: Temperature rise during fire tests: measured gas temperature (φ1), measured and predicted temperature for galvanized IPE (TZ4), assuming an emissivity = 0.32

More recently, Gaigl4 carried out two full-scale tests and 147 laboratory tests to measure the emissivity of galvanized steel. In small-scale laboratory tests, different types of galvanized specimens were heated and the emissivity was deduced by measuring the temperature of the specimens with thermocouples and infrared sensors.

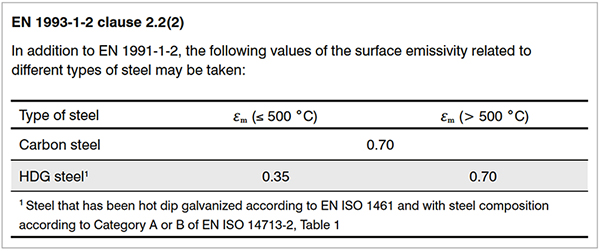

These studies demonstrated consistent emissivity values for a range of galvanized steels with different silicon content. Silicon content is important because its presence can influence the thickness and structure of the galvanized coating. The ranges of silicon content associated with consistent emissivity values of 0.35 were those normally encountered in modern structural steels and are defined by Category A and B of EN ISO 14713-25.

Gaigl also observed that whereas an emissivity of 0.35 was reliably measured for temperatures up to 500°C, at higher temperatures, changes to coating morphology will increase emissivity to approach that of non-galvanized steel (i.e. 0.7).

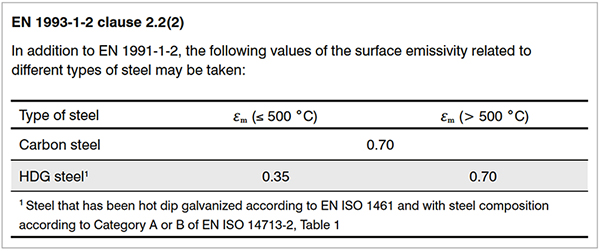

An amendment to Eurocode 3, Part 1.2 Structural Fire Design (EN 1993-1-2)6, largely based on the work of Gaigl, will be included in the next revision of the standard, which is due to be published in 2023. The revision is summarised in Table 1.

Table 1: Proposed revision of EN 1993-1-2 (as at June 2020)

Further fire tests on galvanized steel

Further supporting studies have been carried out in France. Three sets of standard

fire tests were performed at Effectis, France in a joint project by CTICM, Galvazinc and EGGA . In 2016, fire tests were carried out on I and H profile steel columns exposed on four sides. In 2017, further tests were carried out on I and H profile beams exposed on three sides and I profile and hollow section columns exposed on four sides (Figure 6).

Figure 6 Specimens in CTICM- Galvazinc-EGGA tests[9] beam tests (left) and column tests in 2017 (right)

Figure 6 Specimens in CTICM- Galvazinc-EGGA tests[9] beam tests (left) and column tests in 2017 (right)

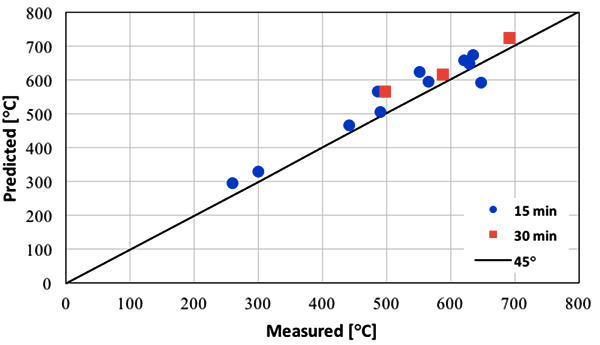

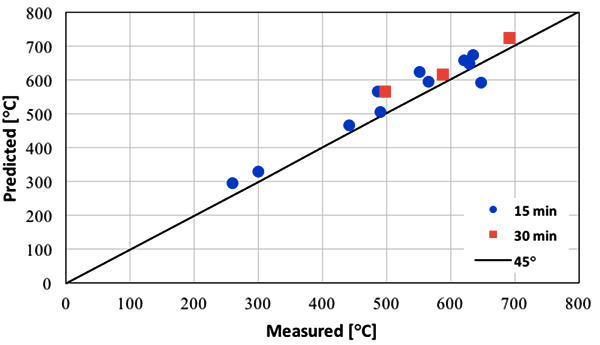

The proposed emissivity for 60 minutes fire resistance was validated through analytical prediction models at CTICM7 and in Prague8. The comparison of predicted and validated results for the surface emissivity εm = 0.35 is shown in Figure 7 for 15 minutes and 30 minutes exposure. These tests show good agreement between the measured and predicted temperatures assuming the surface emissivity = 0.35.

Figure 7 Comparison of predicted surface emissivity εm= 0.35 and measured results for 15 and 30 minutes exposure

References

- SALA, A. Radiant Properties of Materials: Tables of Radiant Values for Black Body and Real Materials, PWN and Elsevier, 1986

- HEINISUO, M. Effect of zinc coating to the resistance of WQ-beam bottom flange in fire, Tampere University of Technology, 2014

- JIRKU, J. and WALD, F. Influence of Zinc Coating to a Temperature of Steel Members in Fire, Journal of Structural Fire Engineering, Vol 6, 2015

- GAIGL, C. and MENSINGER, M. Fire resistance of galvanized structures, 25th International Galvanizing Conference (Intergalva 2018), Berlin, Germany, 2018

- EN ISO 14713-2: 2020 Zinc coatings. Guidelines and recommendations for the protection against corrosion of iron and steel in structures. Hot dip galvanizing, CEN, 2020

- EN 1993-1-2: 2005 Eurocode 3: Design of steel structures – Part 1-2: General rules -Structural fire design, CEN, 2005

- BIHINA, G. Temperature assessment of galvanized steel profiles: validation of proposed emissivity values for bath galvanized steel, Technical report A 30.4.2018), Centre Technique Industriel de la Construction Métallique for the European General Galvanizers Association, 2017

- RASZKOVA, S. Emissivity of hot dip galvanized steel, MS thesis, Czech Technical University in Prague, 2019

Back to top

Figure 1. Temperature rise of galvanized and non-galvanized steel sections subject to the standard nominal fire curve

Figure 1. Temperature rise of galvanized and non-galvanized steel sections subject to the standard nominal fire curve Figure 2 Maximum utilization for galvanized and non-galvanized steel beams exposed to fire on three sides

Figure 2 Maximum utilization for galvanized and non-galvanized steel beams exposed to fire on three sides

Figure 5: Temperature rise during fire tests: measured gas temperature (φ1), measured and predicted temperature for galvanized IPE (TZ4), assuming an emissivity = 0.32

Figure 5: Temperature rise during fire tests: measured gas temperature (φ1), measured and predicted temperature for galvanized IPE (TZ4), assuming an emissivity = 0.32

Figure 6 Specimens in CTICM- Galvazinc-EGGA tests[9] beam tests (left) and column tests in 2017 (right)

Figure 6 Specimens in CTICM- Galvazinc-EGGA tests[9] beam tests (left) and column tests in 2017 (right)